The Electric Bus Heating Dilemma Part 3: Creating the Solution

- Jeremy Sanger

- Aug 20, 2025

- 4 min read

If you have not read Part 1: “Understanding the Issues” and Part 2: “A Practical Solution,” you may want to look them over first.

A proven technology gets a new application

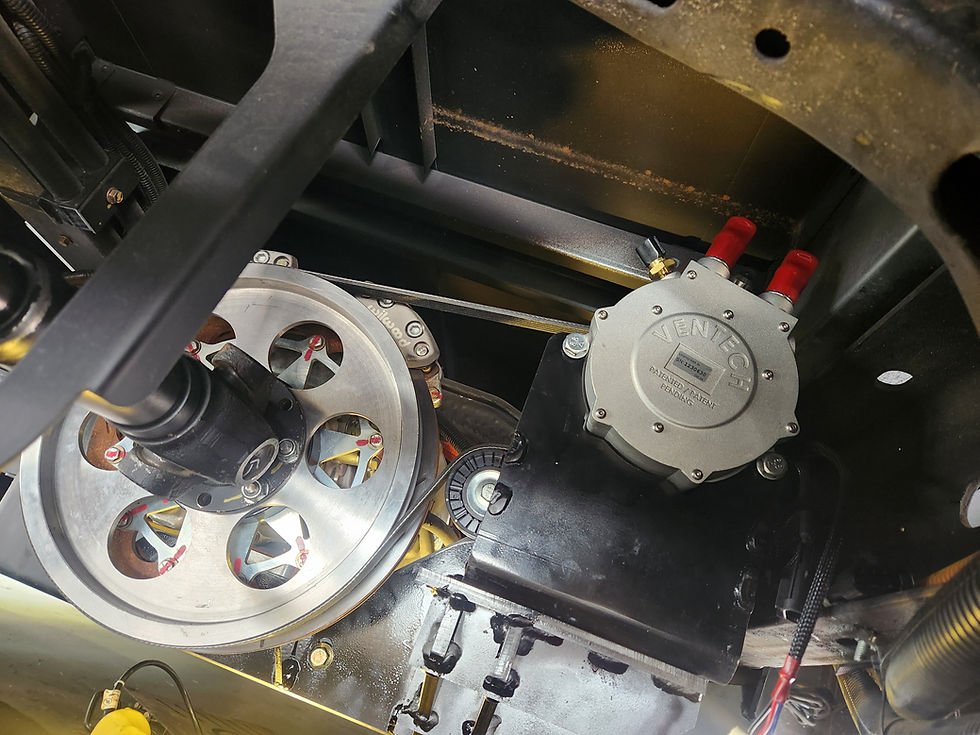

The Ventech LHG (Liquid Heat Generator) produces heat without fuel, electrical resistance, or mechanical friction. How? The short answer is fluid dynamics: Creating and breaking toroidal vortices. This process, and how the LHG does it, is discussed in some detail in our blogs: “What is a Toroidal Vortex?” and “How much heat does an LHG generate?”

Some 25 years ago, Jeremy Sanger, Ventech's owner and founder, came up with the idea for the LHG when he was riding in a cold vehicle in Michigan after having moved here from Great Britain. Since the early 2000’s the LHG has been providing supplemental heat and load management to diesel buses, generators, and light-duty trucks, as well as for Arctic mining, industrial, and transportation equipment.

Heating an EV is not EZ

Not long ago, we were approached by Highland (https://highlandfleets.com/), a leader in fleet electrification. It turns out, heating an EV bus is not EZ to do. Highland was looking for an efficient, affordable way to provide supplemental cabin heat to school buses without the additional cost and energy loss associated with adding more electrical resistance heaters or heat pumps. Why is this harder than it sounds? See our blog, “The Electric Bus Heating Dilemma, Part One: Understanding the issues."

Highland wanted to know if we could develop an LHG-based solution to provide supplemental heat for buses in their electric fleet. A solution that would not require burning fuel, emitting exhaust, or heavy electrical demand. We said we’d give it a shot, and they provided us with a Type A EV Bus to start development.

As you have no doubt gleaned from above, we were already partway there, since the Ventech LHG does not burn fuel or create exhaust when generating heat. The trick was how best to use the LHG technology on an EV Platform.

Power Source & Proof of Concept

It was important to design a Kit that would be easy to install, operate, and maintain. But equally important was where we would obtain the motion to turn the LHG, to generate the heat. Having a separate electric motor to spin the LHG would completely defeat the purpose, since that would draw power directly from the battery - something everyone wanted to avoid.

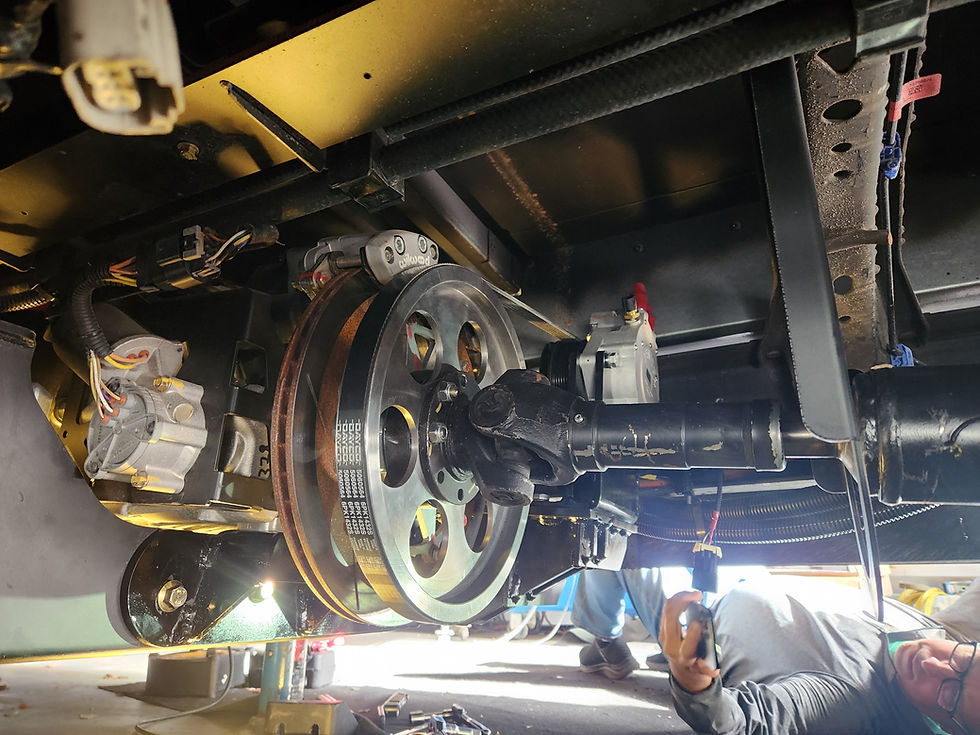

The obvious answer would be to use the kinetic energy from the bus’s motion to turn the LHG and generate heat. That kinetic, "regenerative," energy could be found at the drive shaft. Most importantly, turning the LHG with rotational motion from the driveshaft would allow the LHG to generate heat as the bus slows or goes downhill, producing “regenerative heat” without any draw on the propulsion battery.

Development on the Type-A LHG Kit was completed, and during the 24-25 School year, 5 LHG Kit-equipped Type A EV buses were put in service.

Bigger Goals for the LHG

Once the Type A Kits were in the field, it was time to set our sights on bigger things. Like Type C EV Buses. We had learned some very important lessons from Type A LHG Kit development, like where best to place the LHG and targets for operational programming. And our goals remained the same: easy to install, operate, and maintain.

Highland helped us get two Type C buses to use for development, and we went to work. Thanks to our experience with the Type A Buses, development moved along much more quickly. After a prototype or two (which to the untrained eye didn't look much different from the finished product), the physical elements of the kit were finalized. And, based on Type A experience, our approach to programming was changed as well.

In short, at time of writing (Summer 2025), we have install-ready kits for both Blue Bird and IC Type C EV Buses. Elegant, easy to install, compact, and VERY low maintenance, the LHG Kits for these Type C Buses look good too! A shame you have to be under the bus to look at them.

In Conclusion

At Ventech, because we have a time-proven, efficient, fuel-free heat generation technology, we were able to create an elegant, economical, efficient, regenerative supplemental heat source for Highland, which is now available for any bus fleet that uses these buses.

Also, since we have moved well beyond the conceptual and established the functional application of LHG regenerative supplemental heat for electric buses, we can repeat the process for EV buses of types and from manufacturers beyond those discussed here.

If you have an EV bus that needs supplemental heat, whether whatever the manufacturer or type, contact us - we got this.

Comments